| project |

Details |

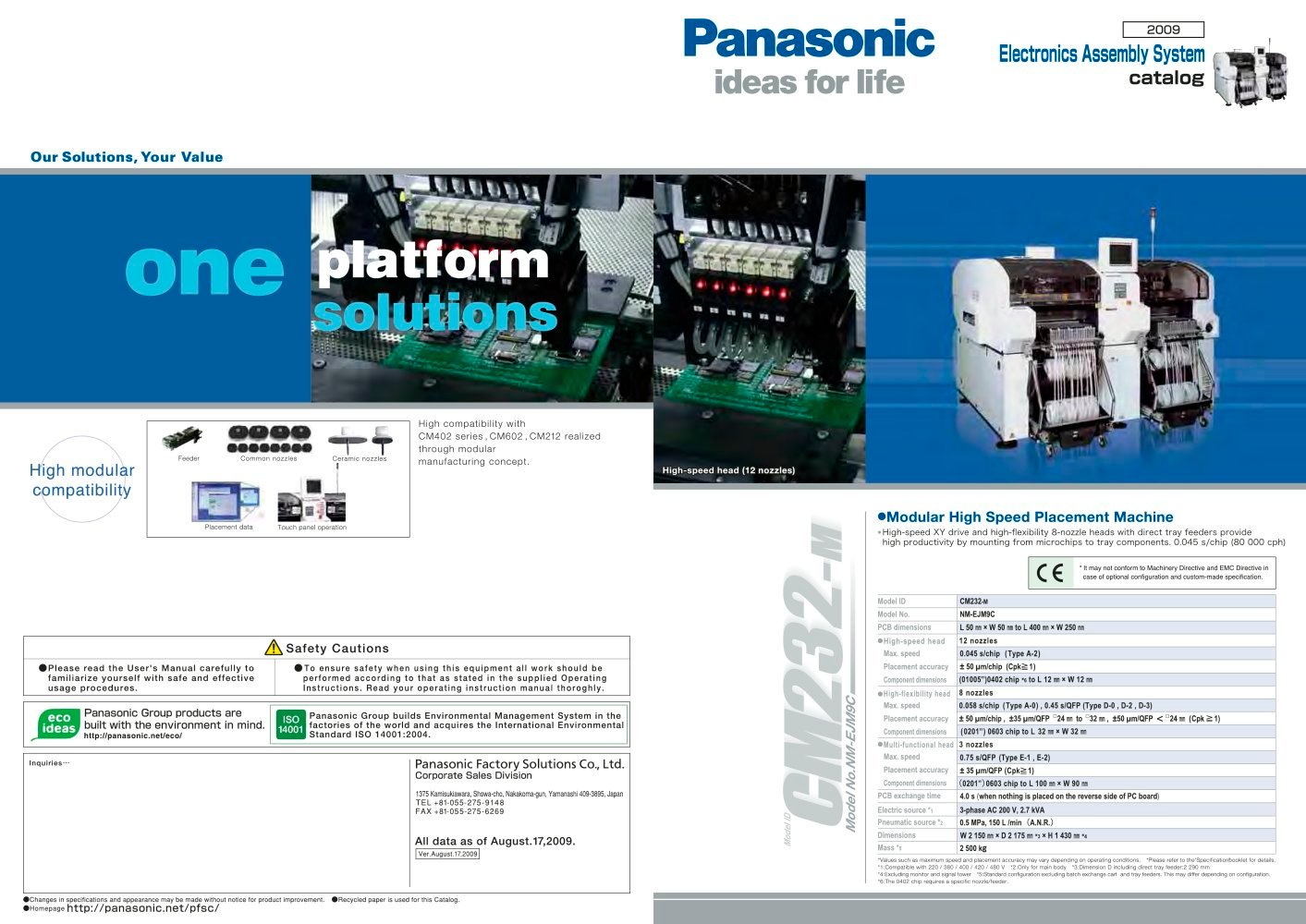

| Placement head system |

Each mounting base is equipped with two sets of mounting heads, identification systems and material rack workbenches. High-speed mounting heads, general mounting heads and multi-functional mounting heads can be selected. |

| High-speed placement head |

12 nozzles are arranged in a 2×6 matrix. Each nozzle is independently driven up and down by a servo motor. The speed of mounting 0603 chips can reach 0.062 seconds/chip. |

| Universal placement head |

8 nozzles are arranged in a 2×4 matrix, which can mount components ranging from tiny to 32mm×32mm. The speed of mounting 0603 chips is 0.068 seconds/chip. |

| Multifunctional placement head |

3 nozzles, each nozzle is equipped with an independent up and down drive system and theta drive system. The nozzle tip placement load can be controlled in real time from 0.5N to 50N according to the data setting. The chip placement speed is 0.21 seconds/chip (the load is controlled between 0.5N and 50N) |

| power supply |

The rated power supply is 3-phase AC 200/220V ±10V, AC 380/400/420/480V ±20V, frequency 50Hz/60Hz, rated capacity 2.7kVA; peak current value during operation 22A (rated voltage AC 200V: 1 cycle). The rated power supply of the auxiliary power supply (HUB power supply: optional) is single-phase AC 100V ~ 240V, frequency 50Hz/60Hz, rated capacity 140VA |

| Air pressure source |

Supply air pressure: minimum 0.5MPa to maximum 0.8MPa (operating air pressure: 0.5MPa to 0.55MPa), supply air volume and consumption air volume are standard 150L/min, when using intelligent bulk material rack (optional), 1 station is 8L/min (standard) |

| Equipment size and weight |

The main body size is 2150mm long × 2175mm wide × 1430mm high (excluding signal tower and touch screen), and the main body weight is 2500kg; the weight of the whole exchange trolley is 81kg/unit; the size when connected to DT40S-20 (optional) is 2150mm long × 2290mm wide × 1430mm high, and the weight of DT40S-20 is 185kg/unit; the standard configuration weight (CM232-M type A2) is 2824kg (1 main body, 4 whole exchange trolleys) |

| Environmental conditions |

Operating temperature: 10℃ to 35℃, humidity: 25%RH to 75%RH (no condensation), altitude: below 1000m |

| control method |

Microcomputer method (VxWORKS) AC servo motor semi-closed loop method (X, Y, Z, θ axis) |

| Instruction method |

X, Y, Z, θ coordinates specification |

| program |

Unlimited number of program types (depending on the hard disk capacity of the PT computer), maximum number of program points is 10,000 points/production line; unlimited number of component libraries (depending on the hard disk capacity of the PT computer), 138 types of high-speed placement heads and 172 types of general placement heads/multi-function placement heads in the standard database |

| Basic performance |

The high-speed placement head (12 nozzles) can mount 0402 chips up to ±0.05mm (Cpk≧1, 0402 chip placement requires a dedicated nozzle and taping rack); the universal placement head (8 nozzles) can mount 0603 and 1005 chips to ±0.05mm (Cpk≧1); the multi-function placement head (3 nozzles) can mount QFP to ±0.035mm (Cpk≧1) |

| Versatility |

In terms of racks, the dozens of tape racks in the past have been unified into 8 types, which can correspond to paper and plastic tapes ranging from 8mm to 104mm. The tape feed is driven by a servo motor, and the feed spacing and speed can be set according to the component. Optional 3D sensor (optional) can detect the flatness of all pins of QFP and other leads, the position and presence of solder balls of CSP, BGA, etc., and adopts laser reflection overall scanning method to achieve high speed and high productivity |

| Applicable substrate |

The minimum substrate size is 50mm×50mm and the maximum is 400mm×250mm; the minimum mounting range is 50mm×44mm and the maximum is 400mm×244mm; the substrate thickness is 0.3mm to 4.0mm; the substrate weight is less than 1.5kg (after installation, including the weight of the carrier) |

| Application Areas |

Widely used in the field of electronic manufacturing, such as consumer electronics (mobile phones, tablets, laptops, etc.), computers and related equipment, communication products, automotive electronics, industrial control equipment, medical electronic instruments, aerospace and military electronic products, smart home devices, power supply equipment, etc. |